- Product Introduction

- Applications

- Technical Parameter

- Process Control

- Function Introduction

- Product Configuration

- After-sale Service

3180 CNC gear hobbing machine is suitable for batch, small batch and single piece production and processing of cylindrical gears and worm gears, as well as short spline shafts with 6 teeth and more than 6 teeth with hobbing length less than 300. And that sprocket can be cut by roll with a sprocket hob. When machining cylindrical gears, reverse milling and forward milling and roll cutting can be used, and the full tooth width can be machined by axial feed (vertical feed). The NC hobbing machine hobbes the common worm gear by radial feed. When CNC hobbing machine processes spline shaft and sprocket, the adjustment and processing method of the machine tool are the same as when machining cylindrical spur gear.

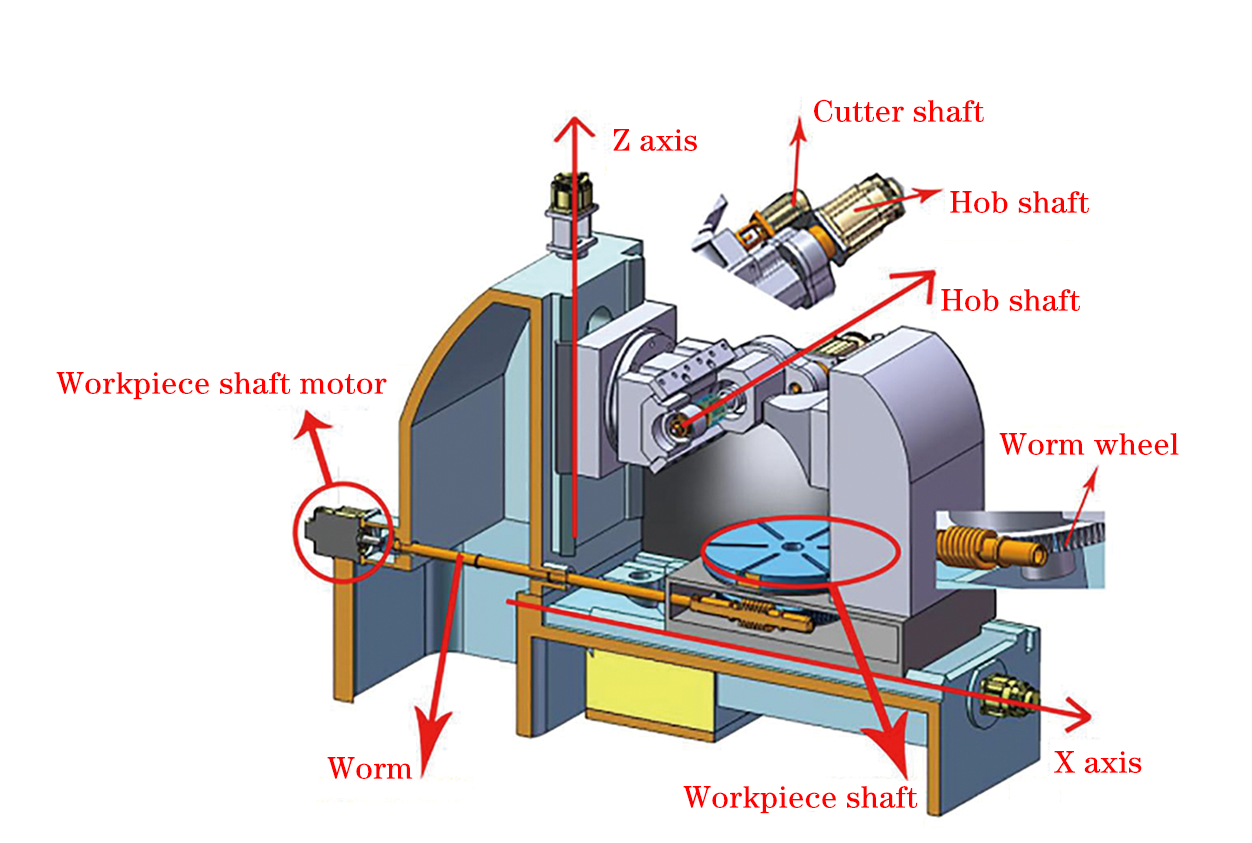

Product structure diagram

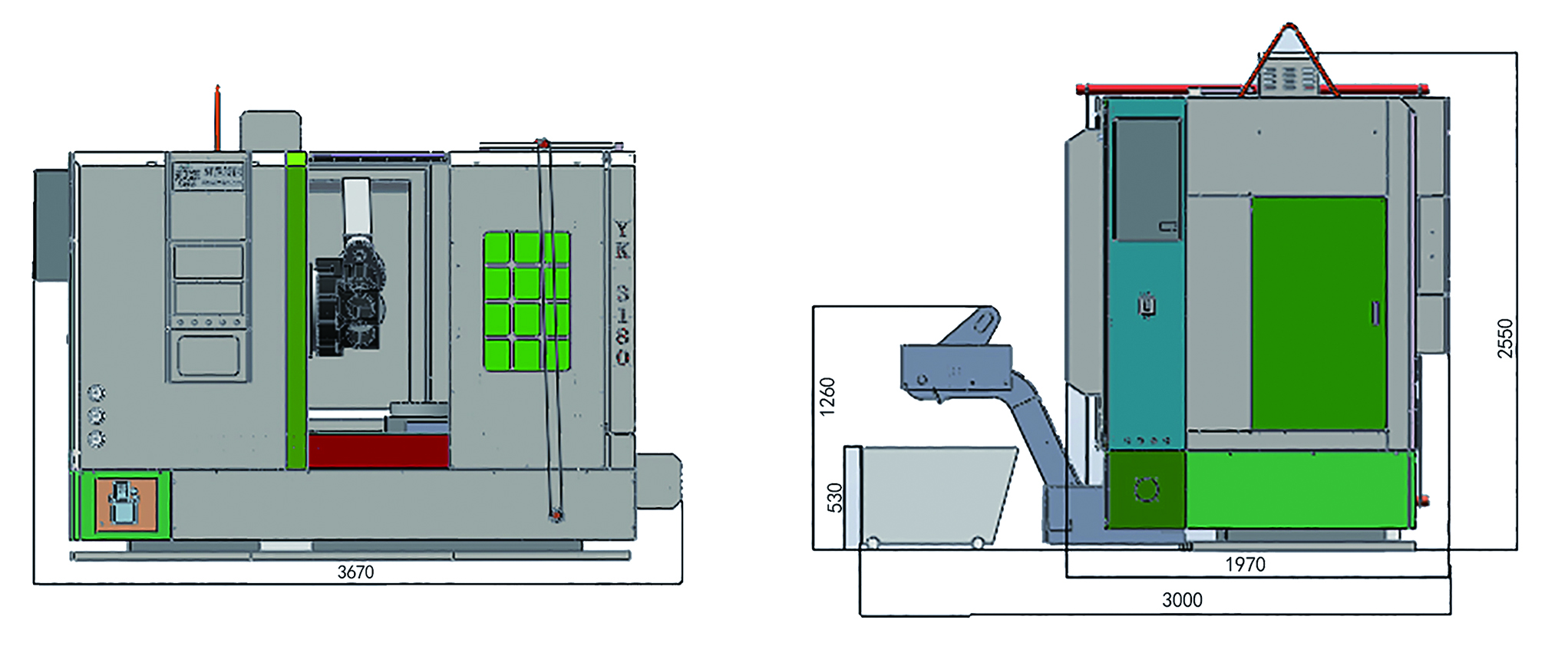

Appearance dimension diagram

YK3150 CNC Hobbing Machine is applicable to the field:

1.Automobile industry: used for processing automobile gears to meet the needs of automobile transmission system.

2.Manufacturing of motorcycles and electric tools: used to manufacture gear parts in motorcycles and electric tools.

3.Manufacturing of reducer: used for processing gears in reducer to improve transmission efficiency and performance of equipment.

4.Instrument manufacturing: used to manufacture gear parts in precision instruments.

5.Other mechanical manufacturing: suitable for all kinds of mechanical equipment manufacturing products that need high-precision gears.

Display of finished products:

|

|

Copper worm wheel Copper worm gear has excellent conductivity, corrosion resistance, high hardness and wear resistance. Copper worm gear is usually made of tin bronze (such as ZCuSn10P1), which contains 10% tin and 1% phosphorus, and the rest is copper. It has high strength, elasticity and good wear resistance, and is suitable for atmospheric, fresh water and seawater environments. In addition, the copper worm gear has good antifriction and corrosion resistance, and can perform well under high-speed sliding and high-load conditions. Copper worm gear is suitable for many fields, mainly including pharmaceutical, chemical and food industries. Copper worm wheels are commonly used in these industries for material crushing equipment, such as speed reducer, small crane, crystal ball grinder, lawn mower, elevator, gate, ship machine, automatic door, coal cake machine, woodworking machinery, harvester, printing and dyeing machine, shredder and so on. |

|

|

Chain wheel Sprocket transmission is suitable for transmission with large center distance and has the characteristics of light weight and low cost. Because the chain has good elasticity and storage capacity of lubricating oil, the sprocket has good buffering capacity and vibration absorption capacity, and can work in harsh environments such as low speed, heavy load, high temperature and dusty. In addition, sprocket drive can ensure accurate transmission ratio and high transmission efficiency (generally up to 0.95~0.97), and the chain does not need great tension, and the load on the shaft and bearing is small. Sprocket is a kind of wheel with embedded chain teeth, which is used to mesh with the block with accurate pitch on the link or cable. Sprockets are widely used in chemical industry, textile machinery, escalators, wood processing, three-dimensional parking garages, agricultural machinery, food processing, instrumentation, petroleum and other industries. |

|

|

Spline shaft Spline shaft is a kind of mechanical transmission, which transmits mechanical torque just like flat key, semi-circular key and inclined key. There are longitudinal keyways on the outer surface of the shaft, and the rotating parts sleeved on the shaft also have corresponding keyways, which can keep synchronous rotation with the shaft. While rotating, some can also slide longitudinally on the shaft, such as gear shifting of gearbox. The spline shaft has the advantages of strong bearing capacity, stable transmission, compact structure, high transmission efficiency, convenient installation, high transmission precision, long service life and wide application range. Spline shafts are widely used, mainly including aircraft, automobiles, tractors, machine tool manufacturing, agricultural machinery and general mechanical transmission devices. |

|

|

Gear As a common mechanical transmission element, gear has the characteristics of high transmission precision, high transmission efficiency, wide transmission ratio range, compact structure and so on. At the same time, it has strong wear resistance, strong bearing capacity, low noise, long life and high reliability. As the core component of mechanical transmission, gear plays an irreplaceable role in many key industrial fields. First of all, in the field of machining, gear is an important guarantee for the accurate and stable realization of machine tool action, which can transform the high-speed rotation of motor into the low-speed and high-torque movement required by equipment. Secondly, the automobile field is also inseparable from gears. Whether it is a transmission, a rear axle or a steering gear, gears are needed to realize power transmission and adjustment. In addition, in the aviation field, gears are the key components of engines and various control surfaces, which require extremely high strength, temperature and weight. At the same time, CNC machining in the field of machine tools can not be separated from gears, which can achieve high-precision and high-speed machining through gears with different sizes and proportions. Finally, gear transmission system also plays a vital role in blast furnace and rolling mill in metallurgical field. In a word, gears play a key role in machining, automobile, aviation, machine tools, metallurgy and other fields, and are indispensable elements in industrial development. |

|

NO |

Project |

Parameter |

|

|

1 |

Processing parameters |

Working Table diameter |

550mm |

|

2 |

Maximum workpiece diameter |

550mm/800mm(The small column needs to be removed) |

|

|

3 |

Maximum machining modulus |

8mm |

|

|

4 |

Maximum machining helix angle |

±40° |

|

|

5 |

Maximum machining length (Z stroke) |

350mm |

|

|

6 |

Minimum center height from workbench to hob |

235mm |

|

|

7 |

Maximum speed of workbench |

30RPM |

|

|

8 |

The maximum and minimum distance range from the end face of the external support to the workbench. |

400-600mm |

|

|

9 |

Hob parameters |

Maximum tool installation diameter * length |

φ160*160mm |

|

10 |

Maximum amount of cutter shifting of hob |

200mm |

|

|

11 |

Taper hole of tool spindle |

Mohs NO.5 |

|

|

12 |

Distance from tool spindle axis to workbench axis |

30-500mm |

|

|

13 |

Hob speed series |

Infinitely variable speeds |

|

|

14 |

Hob speed range |

0-600r/min |

|

|

15 |

Axial feed series |

Stepless feed |

|

|

16 |

Axial feed range |

0.1-2mm/r |

|

|

17 |

Other |

Total power of equipment |

21KW |

|

18 |

Volume (length * width * height) (m) |

3.4*2.2*2.3 |

|

|

19 |

Total weight of machine tool |

6T |

|

|

20 |

Functional part |

Control form |

system control |

|

21 |

Transmission form |

Electronic gearbox |

|

|

22 |

Differential form |

Electronic differential |

|

|

23 |

Lubrication form |

Automatic centralized timing quantitative lubrication |

|

|

24 |

Hob material |

Cemented carbide/high speed steel |

|

|

25 |

Cutting cooling form |

Oil cooling |

|

|

26 |

Sheet metal form |

Full protection car body panel repair |

|

|

27 |

Machining gear form |

Straight, helical, worm gear |

|

|

28 |

Configuration form |

control system |

“KND” |

|

29 |

(C-axis) High-precision servo motor for hob shaft |

KND 11KW |

|

|

30 |

(B-axis) high-precision servo motor for workpiece axis |

KND 4.4KW |

|

|

31 |

X-direction high precision servo motor |

KND 2.3KW |

|

|

32 |

Z-direction high precision servo motor |

KND 2.3KW |

|

|

33 |

(Y-axis) high-precision servo motor for tool shifting axis |

KND 1.0KW |

|

|

34 |

ball screw |

Overall grinding P3-P4 |

|

|

35 |

Worm gear |

double-end |

|

|

36 |

Hob mandrel |

One set of φ22, φ27, φ32 and φ40 respectively |

|

|

NO |

Working procedure |

Superiority |

Picture |

|

1 |

Scraping of contact surface between parts |

1. After scraping, the surface flatness is better, the contact is better, and there are more contact points, and it has the function of hardening the surface and strengthening the wear resistance. |

|

|

2. The scraping surface quality is evaluated by the number of contact points per unit area, and the adopted standard is 12-16 points /25*25mm. |

|

||

|

2 |

Laser interferometer detection |

It can analyze the dynamic characteristics of the ball screw of machine tool, the response characteristics of the driving system and the dynamic characteristics of the guide rail, etc., with high accuracy and efficiency, and provide a basis for machine tool error correction. |

|

|

3 |

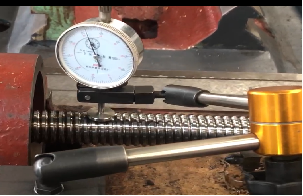

Ball screw drive assembly |

In the assembly, the parallelism between the ball screw and the guide rail is adjusted by grinding the screw nut seat, and the control requirement is 0.01 mm/300 mm. |

|

|

4 |

Spindle assembly |

The assembly process is assembled in a constant temperature workshop to ensure the accuracy and quality in the assembly process. After the assembly, the spindle needs to be tested for abnormal sound and temperature rise before installation, and it can only be installed after it is confirmed that there is no problem. |

|

|

5 |

Gear detector checks the accuracy of products processed by hobbing machine. |

Gear measuring instruments can measure and evaluate various precision indexes of gears according to international and national standards, such as GB/T10095-2001 (equivalent to ISO1328:1997). These indexes include tooth profile deviation, helix deviation, tooth pitch deviation, radial runout and so on. |

|

|

|

NO |

Part |

Function |

|

Mechanical part |

1 |

Hob shaft |

Rotating speed: 0-600r/min, stepless speed regulation. |

|

2 |

Workpiece shaft (table) |

Double-headed worm gear transmission adopts servo motor gear differential reduction, with the rotation speed of 0-30r/min and stepless speed change. |

|

|

3 |

Slideway |

Adopt hard rail mode and ball screw drive. |

|

|

4 |

Tailstock |

Hydraulic form, the pressure can be adjusted. |

|

|

5 |

Hydraulic pump station |

The hydraulic and cooling circulation systems are separated to avoid mixing with each other. |

|

|

6 |

Lubrication system |

Automatic centralized timing and quantitative lubrication, with fault alarm function, can automatically execute lubrication program when starting. |

|

|

7 |

Chip removal (optional) |

Adopt automatic chip removal machine |

|

|

Electrical part |

1 |

System |

Kaiendi K1000TF1i customization system can process straight teeth, helical teeth and worm wheels, with filling operation, which is reliable, simple and easy to learn. |

|

2 |

Actuating motor |

KND |

|

|

3 |

Number of axles |

Five-axis four-linkage |

|

|

4 |

Gear case |

Electronic gearbox |

NO

Name

Factory

Picture

1

Lead screw

JIANGSU QIJIAN

2

Bearing

LUOYANG Bearing research ZYS

3

Principal axis

YUHUAN LIYANG

4

System

KND

5

Electrical machinery

KND

7

Hob arbor

LIHE, CIXI GUTANG

8

Hydraulic pump station

ANHUI QINLI

9

Worm wheel, worm

CHONGQING QIDAYUAN/CHANGZHOU MAILAIGU

选配配件

NO

Name

Eactory

Picture

Price

1

Electric cabinet air conditioner

XUZHOU KEHENG 'Ao

¥4,200yuan

2

Oil mist separator

YUHUAN XINXIN

¥8,000yuan

3

Additional price difference caused by replacing the new generation system

SYNTEC

¥8,000yuan

4

Hob mandrels

(φ22、φ27、φ32、φ40)

LIHE, CIXI GUTANG

¥1,200yuan/root

5

Chip conveyor

CANGZHOU GAOLONG

2. The quality guarantee period shall come into effect on the date when both parties sign and confirm the final acceptance of the contract goods.

3. During the warranty period, Party B shall provide timely and free maintenance services for all kinds of failures and damages of equipment due to quality reasons, and replace the failed parts free of charge; If Party A stops working due to machine tool failure, Party B shall reply within 8 hours after receiving Party A's notice.

4. After the warranty period of the machine tool, Party B will provide timely technical guidance and spare parts supply at preferential and reasonable prices according to Party A's requirements.