- Product Introduction

- Applications

- Technical Parameter

- Process Control

- Function Introduction

- Product Configuration

- After-sale Service

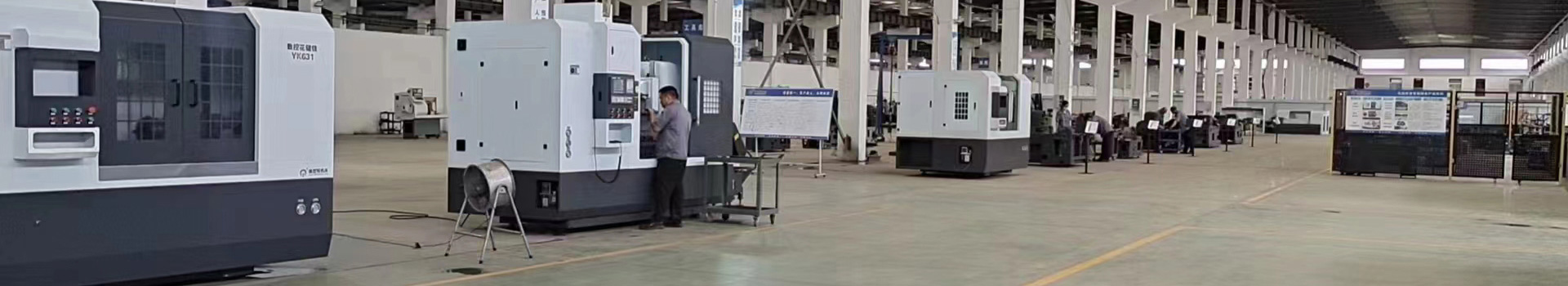

YK631 CNC spline milling is a five-axis and four-linkage CNC horizontal gear hobbing machine, which is mainly used for machining straight and helical cylindrical gears with a modulus of ≤4mm, and can also be used for worm gear machining by radial method. This equipment is especially suitable for machining long-axis gears such as automobile brake camshaft, automobile half shaft and transmission shaft.

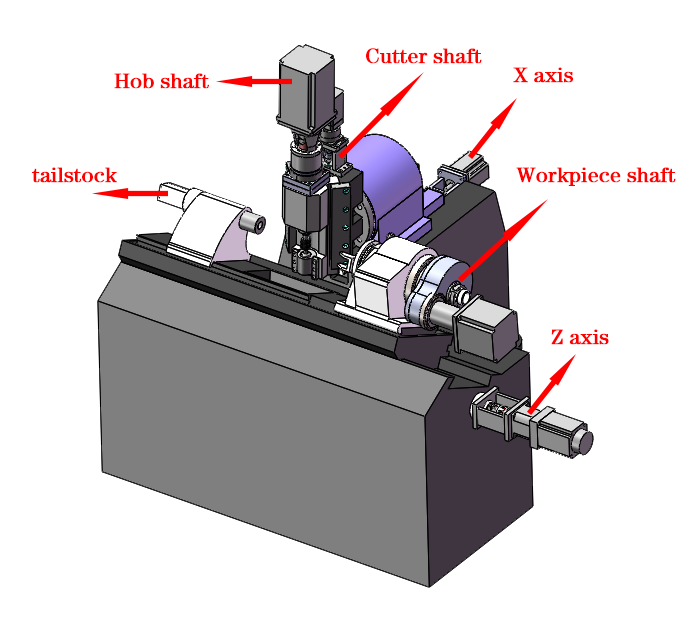

Product structure diagram

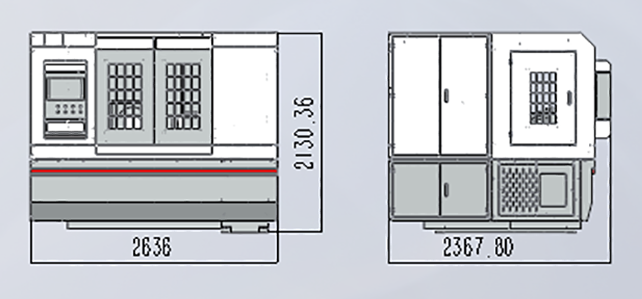

outline dimensional drawing

|

|

Spline shaft Spline shaft is a kind of mechanical transmission, which transmits mechanical torque just like flat key, semi-circular key and inclined key. There are longitudinal keyways on the outer surface of the shaft, and the rotating parts sleeved on the shaft also have corresponding keyways, which can keep synchronous rotation with the shaft. While rotating, some can also slide longitudinally on the shaft, such as gear shifting of gearbox. The spline shaft has the advantages of strong bearing capacity, stable transmission, compact structure, high transmission efficiency, convenient installation, high transmission precision, long service life and wide application range. Spline shafts are widely used, mainly including aircraft, automobiles, tractors, machine tool manufacturing, agricultural machinery and general mechanical transmission devices. |

|

|

Semiaxis Semi-axle, also known as drive shaft or transmission shaft, is mainly used to connect the differential and drive wheel of the vehicle and transmit torque. It is usually made of a hollow steel tube with splines or square teeth inside to connect with the differential and the driving wheel. The structure of the semi-axle is relatively simple, but it bears a large torque, so it needs to have certain strength and rigidity. The application scope of the semi-axle mainly includes passenger cars, commercial vehicles with small total mass and commercial vehicles with large total mass. |

|

|

Gear shaft Gear shaft refers to a mechanical part that supports rotating parts and rotates with them to transmit motion, torque or bending moment. Generally, it is a metal rod, and each segment can have different diameters. The rotating parts in the machine are mounted on the shaft. Gear shaft has the characteristics of high transmission efficiency, strong bearing capacity, wide applicability, low maintenance cost and long service life, so it is widely used in industrial production and machinery manufacturing fields such as automobile industry, aerospace, construction machinery, paper industry, electric power industry and so on. |

|

NO |

Project |

Parameter |

|

|

1 |

technical parameter |

Diameter of spindle through hole |

70 |

|

2 |

Maximum machining modulus across the board |

4mm |

|

|

3 |

Maximum machining helix angle |

±45° |

|

|

4 |

Maximum machining length |

600mm |

|

|

5 |

Hob speed series |

Infinitely variable speeds |

|

|

6 |

Hob speed range |

0-1500r/min |

|

|

7 |

Axial feed series |

Endless feed |

|

|

8 |

Axial feed range |

0.1-4mm/r |

|

|

9 |

Functional part |

Control form |

System control |

|

10 |

Transmission form |

Electronic gearbox |

|

|

11 |

Differential form |

Electronic differential |

|

|

12 |

Lubrication form |

Automatic centralized timing quantitative lubrication |

|

|

13 |

Hob material |

Cemented carbide/high speed steel |

|

|

14 |

Cutting cooling form |

Oil cooling and air cooling |

|

|

15 |

Sheet metal form |

Without |

|

|

16 |

Machining gear form |

Straight, helical, worm gear |

|

|

17 |

Configuration form |

Control system |

KND |

|

18 |

Hob power head |

XUANMAN custom made |

|

|

19 |

Hob shaft motor |

NAZHI or HUADA 7.5KW |

|

|

20 |

Workpiece shaft motor |

NAZHI or HUADA 4.4KW |

|

|

21 |

Z-direction motor |

NAZHI or HUADA 1.3KW |

|

|

22 |

X-direction motor |

NAZHI or HUADA 1.3KW |

|

|

23 |

Tool-shifting motor |

NAZHI or HUADA 1.0KW |

|

|

NO |

Working procedure |

Superiority |

Picture |

|

1 |

Sliding table scraping |

After scraping, the surface flatness is better, the contact is better, and there are more contact points, and it has the function of hardening the surface and strengthening the wear resistance. |

|

|

2 |

Table scraping |

After scraping, the surface flatness is better, the contact is better, and there are more contact points, and it has the function of hardening the surface and strengthening the wear resistance. |

|

|

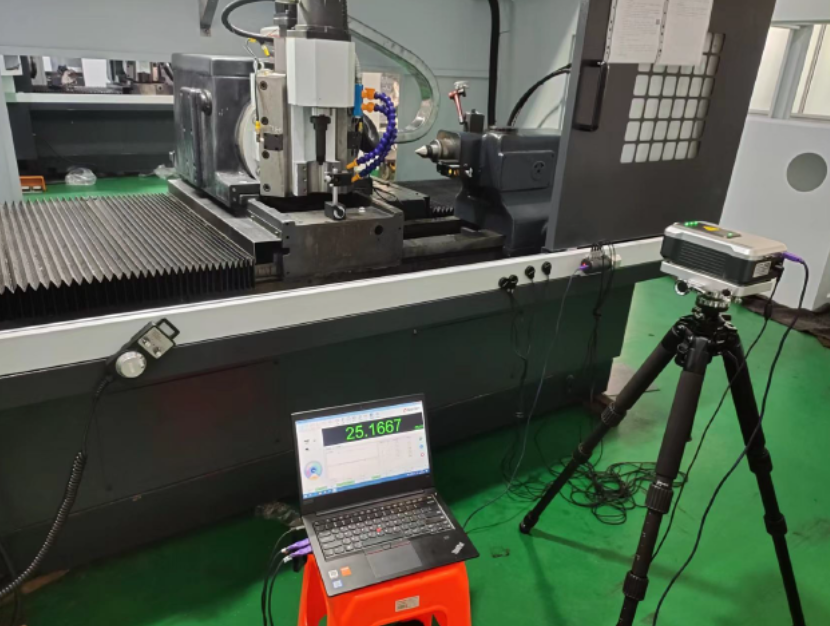

3 |

Laser interferometer detects repeated positioning accuracy. |

It can analyze the dynamic characteristics of the ball screw of machine tool, the response characteristics of the driving system and the dynamic characteristics of the guide rail, etc., with high accuracy and efficiency, and provide a basis for machine tool error correction. |

|

|

4 |

Whole machine debugging |

|

|

|

|

NO |

Part |

Function |

|

Mechanical part |

1 |

Hob shaft |

The servo motor is directly connected, the rotation speed can reach 0-1500r/min, the stepless speed regulation is realized, and the hob can automatically run. |

|

2 |

Workpiece shaft |

Instead of bearing structure, the front flange of the spindle can be equipped with chuck, the through hole of the spindle is 70mm, and the servo motor gear is used for differential deceleration, with a speed of 0-500r/min and stepless speed change, and the front pneumatic chuck is added at the tail end. |

|

|

3 |

slideway |

It is changed to ball screw pair transmission, and the guide rail remains the same. |

|

|

4 |

tailstock |

Change to hydraulic form, and the pressure can be adjusted. |

|

|

5 |

Hydraulic pump station |

Independent plug-in, separated from the cooling circulation system, to avoid mixing. |

|

|

6 |

lubrication system |

Automatic centralized timing and quantitative lubrication, with fault alarm function, can automatically execute lubrication program when starting. |

|

|

7 |

chip removal |

without |

|

|

8 |

Oil mist treatment |

without |

|

|

Electrical part |

9 |

system |

"KND" gear hobbing system can process straight teeth, helical teeth and worm wheels, and it is reliable, simple and easy to learn. |

|

10 |

electrical machinery |

NAZHI or HUADA |

|

|

11 |

number of axles |

Five axes and three linkages |

|

|

12 |

gear case |

Electronic gearbox |

2. The quality guarantee period shall come into effect on the date when both parties sign and confirm the final acceptance of the contract goods.

3. During the warranty period, Party B shall provide timely and free maintenance services for all kinds of failures and damages of equipment due to quality reasons, and replace the failed parts free of charge; If Party A stops working due to machine tool failure, Party B shall reply within 8 hours after receiving Party A's notice.

4. After the warranty period of the machine tool, Party B will provide timely technical guidance and spare parts supply at preferential and reasonable prices according to Party A's requirements.